In recent years, the term 3D Printing is well known famous among various homemakers or hobbyists. And the process of this is also known by “Addictive Manufacturing’ and this technology has been around since the 1980s.

The term 3D printing surrounds various technologies that build machine parts layer by layer. Each varies in the selection and can differ in material quality, durability and technologies, and most important price.

There are various types of 3D printing which includes

1. Multi Jet Fusion (MJF)

2. Fused Deposition Modeling (FDM)

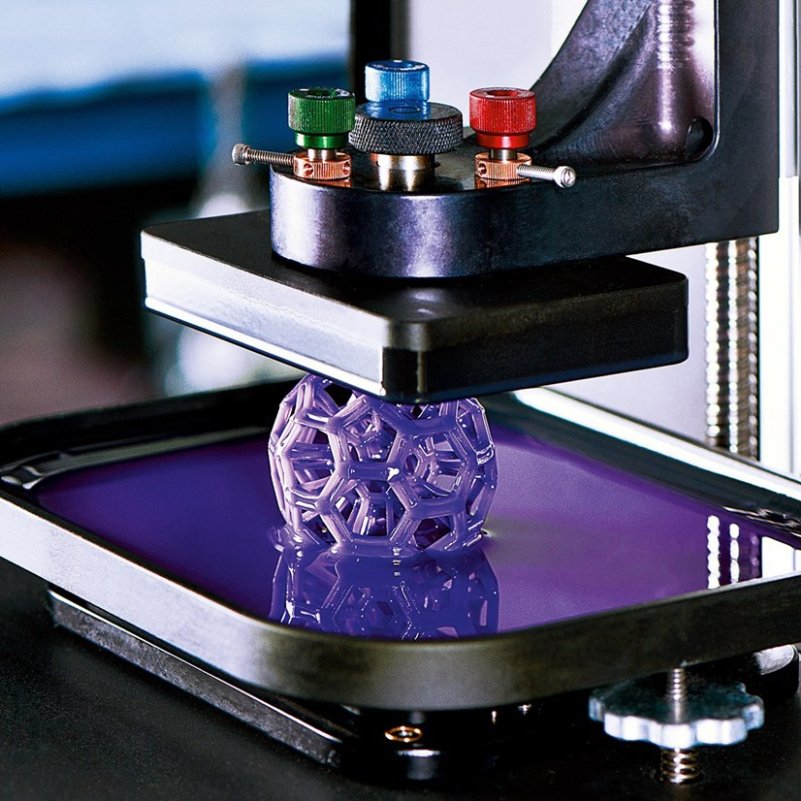

3. Stereolithography (SLA)

4. Digital Light Processing (DLP)

5. PolyJet

6. Power Bed Fusion

Multi Jet Fusion

The most frequent process used for 3D Printing is Multi Jet. Multi Jet technology is somewhat different from other types of printing technologies but most like 2D printing technology. In this technology deposition of material is through inkjet without the use of the bed.

The most common materials used in Jet Fusion are rubber, ABS, and various other polymers used in the SLA process.

It is one of the most accurate additive technologies and this process also allows different materials to be used in single object design. The benefit of this process is the accelerated build time which lowers the production cost.

Fused Deposition Modeling

This technology is one of the most common 3D Printing technologies to form a part or object from the plastics. In this technology a material is molted and deposited layer by layer to form an object. Materials include in this are PLA, Polycarbonate, and many others. The main advantages of this printing technology are it is cost-effective and creates models/objects in no time. Examples of printers using this technology are SOVOL SV01, BIQU B1, CREALITY Ender 3 v2 and ENDER 3 S1 3D Printer.

Stereolithography (SLA)

It is one of the first and original 3d printing technology developed IN 1986 called SLA. It works on a mechanism called Polymerization which exposed to the Energy through UV layer producing objects/models with high finishes, smooth and tight tolerance. The most common industry where this SLA technology is used in the medical applications.

Digital Light Processing (DLP)

It is somewhat like Polymerization mechanism which SLA uses. The main difference is that this DLP technology uses digital light screen and SLA uses UV layer which results in faster build speed.

PolyJet

It is another 3D Printing process and it fabricate the objects or models with different colors and materials. We are not recommending this technology if you looking to design a single object, rigid model, instead of this go for SL & SLS prototyping technology.

Where to Buy Leister in Austr...

Environmental Stress can affec...

How Custom Home Builders Creat...

Secure Global Synchronized FX ...

Everything You Need to Know Ab...

Discover Transformation at Our...

Family-Friendly Winter Activit...

Kinima Physio - The Go-To Clin...

Is Your Old Car Just Sitting T...

The Ultimate Guide to Home Bui...